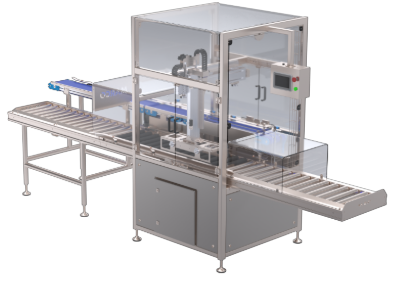

TrayMaster

Reliable Clamshell Pick & Place

The MARCO TrayMaster is designed for the seamless handling of punnets and clamshells. This state-of-the-art system ensures precise picking and placing, accurately packing products into boxes or trays while minimising manual labour and eliminating the strain of repetitive lifting.

The TrayMaster’s innovative clamp mechanism gently picks and places products without damage, utilising a linear actuator for straightforward maintenance and repair.

Videos

| Technical Specifications | |

| Size (W x H x D) | 4264 x 2050 x 1060 mm |

| Key Features | ▪ User friendly operator HMI to easily select products or add new ones. ▪ Capable of processing up to 20 cycles per minute, typically arranged in 2 rows per box (dependent on pack and presentation format). ▪ Compact footprint allows for efficient use of floor space. |

TrayMaster

Reliable Clamshell Pick & Place

MARCO TrayMaster is designed for the seamless handling of punnets and clamshells. This state-of-the-art system ensures precise picking and placing, accurately packing products into boxes or trays while minimising manual labour and eliminating the strain of repetitive lifting.

The TrayMaster’s innovative clamp mechanism gently picks and places products without damage, utilising a linear actuator for straightforward maintenance and repair.

Videos

| Technical Specifications | |

| Size (W x H x D) | 4264 x 2050 x 1060 mm |

| Key Features | ▪ User friendly operator HMI to easily select products or add new ones ▪ Capable of processing up to 20 cycles per minute, typically arranged in 2 rows per box (dependent on pack and presentation format) ▪ Compact footprint allows for efficient use of floor space |

| Options | ▪ Vision System Crate Reject ▪ Lane Divert |