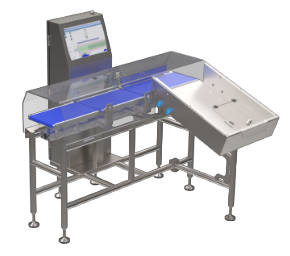

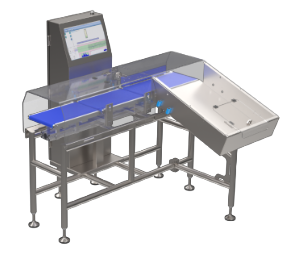

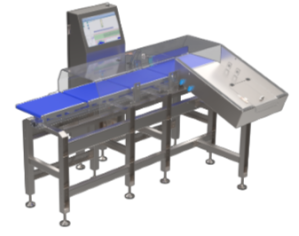

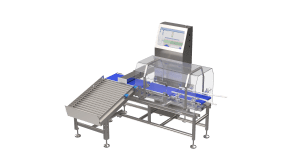

MCW3 Checkweigher

Smart Control – Total Visibility

This durable, hygienic 3-belt checkweigher guarantees every pack meets exact weight specs, ensuring quality and compliance. Real-time weighing and automatic diversion of out-of-tolerance packs keep your line accurate and efficient.

With a 15.6″ touchscreen and MARCO Yield Control integration, you get instant feedback and full production visibility, right from your desk.

| Technical Specifications | |

| Size (WxHxD) | 1531 x 1424 x 1476 mm |

| Belt Weight Checking System | Three-belt |

| Maximum Product Dimension (LxWxH) | 330mm x 200mm x 150mm |

| Belt Width | 250mm |

| Speed | Up to 120ppm(pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Compact Footprint ▪ Supermarket Compliant ▪ UK Weights and Measures approved ▪ Rejects product to a lockable bin ▪ Bin full confirmation sensor ▪ Optional Metal Detector |

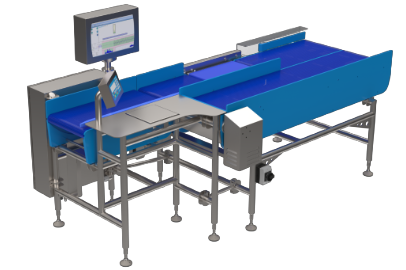

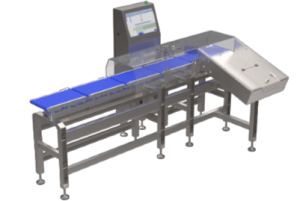

MCW4 Checkweigher

Efficiency and Compliance – Perfectly Balanced

This robust 4-belt checkweigher guarantees every pack meets exact weight specs for consistent quality and compliance. Four synchronised belts with integrated load cells deliver real-time accuracy, while out-of-tolerance packs are automatically diverted to keep your line efficient.

With a 15.6″ touchscreen and MARCO Yield Control integration, setup and monitoring are simple, giving you complete control at a glance.

| Technical Specifications | |

| Size (WxHxD) | 2000 x 1474 x 1526 mm |

| Belt Weight Checking System | Four-belt |

| Maximum Product Dimension (LxWxH) | 220mm x 330mm x 120mm |

| Belt Width | 250mm |

| Speed | Up to 140ppm (pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Supermarket Compliant ▪ UK Weights and Measures approved ▪ Rejects product to a lockable bin ▪ Bin full confirmation sensor ▪ Optional Metal Detector |

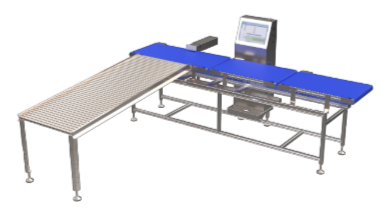

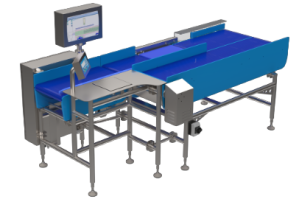

MCW5 Checkweigher

Unmatched Accuracy for High-Throughput Lines

This high-performance 5-belt checkweigher ensures smooth handling and precise weight verification at high throughput. Advanced load cells measure in real time, automatically diverting out-of-tolerance packs to keep your line efficient and compliant.

With a 15.6″ touchscreen and MARCO Yield Control integration, setup and monitoring are simple, giving you complete control.

| Technical Specifications | |

| Size (WxHxD) | 2462 x 1447 x 1456 mm |

| Belt Weight Checking System | Five-belt |

| Maximum Product Dimension (LxWxH) | 220mm x 330mm x 150mm |

| Belt Width | 250mm |

| Speed | Up to 160ppm (pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Supermarket Compliant ▪ UK Weights and Measures approved ▪ Rejects product to a lockable bin ▪ Bin full confirmation sensor ▪ Optional Metal Detector |

MCW Rework Checkweigher

Smart Rework for Perfect Packs

MCW Rework guarantees every open pack hits exact weight before sealing. It safeguards your brand, cuts waste, and boosts efficiency by auto-diverting out-of-spec packs.

Stay compliant and customer-focused with easy rework and precision monitoring, powered by a 15.6″ touchscreen and full MARCO Yield Control integration.

Videos

| Technical Specifications | |

| Size (WxHxD) | 2462 x 1447 x 1456 mm |

| Belt Weight Checking System | Five-belt |

| Maximum Product Dimension (LxWxH) | 200mm x 200mm x 120mm |

| Belt Width | 250mm |

| Speed | Up to 90ppm (pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Designed for open products to make corrective adjustments pre-seal/close ▪ Supermarket Compliant ▪ UK Weights and Measures approved |

MCW Bulk XL

Built for Big Performance

Built for larger, bulkier items, this robust checkweigher ensures every pack meets exact weight specs before sealing. It cuts waste, boosts efficiency, and safeguards compliance.

With a 15.6″ touchscreen and MARCO Yield Control integration, you get real-time feedback and full production visibility, maximising throughput while protecting your brand.

| Technical Specifications | |

| Size (WxHxD) | 2841mm x 1391mm x 2915mm |

| Belt Weight Checking System | Three-belt |

| Maximum Product Dimension (LxW) | 700mm x 500mm |

| Belt Width | 500mm |

| Speed | Up to 30ppm |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Food grade belts ▪ Direct integration with MARCO YCM ▪ Up/downstream interlock connection ▪ Anti-gravity roller reject conveyor |

| Options | 2m Roller Reject Conveyor |

MCW Carton

Seal Confidence into Every Carton

Built for high-volume carton handling, the MCW Carton ensures precise weight control. This heavy-duty system boosts efficiency and cuts waste by flagging out-of-spec cartons early.

Operators enjoy fast setup via a 15.6″ touchscreen, while full MARCO Yield Control integration delivers real-time feedback and office-level oversight.

| Technical Specifications | |

| Size (WxHxD) | 1543mm x 1391mm x 1566mm |

| Belt Weight Checking System | Three-belt |

| Maximum Product Dimension (LxWxH) | 330 x 220 x 230mm |

| Belt Width | 240mm |

| Speed | Up to 60cpm |

| Reject Method | Pusher |

| Key Features | ▪ Food grade belts ▪ Direct integration with MARCO YCM ▪ Visual Beacon Alarm Mode |

MCW3 Checkweigher

Smart Control – Total Visibility

This durable, hygienic 3-belt checkweigher guarantees every pack meets exact weight specs, ensuring quality and compliance. Real-time weighing and automatic diversion of out-of-tolerance packs keep your line accurate and efficient. With a 15.6″ touchscreen and MARCO Yield Control integration, you get instant feedback and full production visibility, right from your desk

The MCW3 ensures product consistency by verifying that each package meets the customer’s specified weight requirements. As items move along the production line, the conveyor scale accurately measures individual pack weights. Any packs falling outside the predetermined specifications is automatically identified and diverted to a reject bin for manual inspection.

| Technical Specifications | |

| Size (WxHxD) | 1531 x 1424 x 1476 mm |

| Belt Weight Checking System | Three-belt |

| Maximum Product Dimension (LxWxH) | 330mm x 200mm x 150mm |

| Belt Width | 250mm |

| Speed | Up to 120ppm(pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Supermarket Compliant ▪ UK Weights and Measures approved ▪ Rejects product to a lockable bin ▪ Bin full confirmation sensor ▪ Optional Metal Detector |

MCW4 Checkweigher

Efficiency and Compliance – Perfectly Balanced

This robust 4-belt checkweigher guarantees every pack meets exact weight specs for consistent quality and compliance. Four synchronised belts with integrated load cells deliver real-time accuracy, while out-of-tolerance packs are automatically diverted to keep your line efficient.

With a 15.6″ touchscreen and MARCO Yield Control integration, setup and monitoring are simple, giving you complete control at a glance.

| Technical Specifications | |

| Size (WxHxD) | 2000 x 1474 x 1526 mm |

| Belt Weight Checking System | Four-belt |

| Maximum Product Dimension (LxWxH) | 220mm x 330mm x 120mm |

| Belt Width | 250mm |

| Speed | Up to 140ppm (pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Supermarket Compliant ▪ UK Weights and Measures approved ▪ Rejects product to a lockable bin |

MCW5 Checkweigher

Unmatched Accuracy for High-Throughput Lines

This high-performance 5-belt checkweigher ensures smooth handling and precise weight verification at high throughput. Advanced load cells measure in real time, automatically diverting out-of-tolerance packs to keep your line efficient and compliant.

With a 15.6″ touchscreen and MARCO Yield Control integration, setup and monitoring are simple, giving you complete control.

| Technical Specifications | |

| Size (W x H x D) | 2462 x 1447 x 1456 mm |

| Belt Weight Checking System | Five-belt |

| Maximum Product Dimension (LxWxH) | 220mm x 330mm x 150mm |

| Belt Width | 250mm |

| Speed | Up to 160ppm (pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Supermarket Compliant ▪ UK Weights and Measures approved ▪ Rejects product to a lockable bin ▪ Bin full confirmation sensor ▪ Optional Metal Detector |

MCW Rework Checkweigher

Smart Rework for Perfect Packs

MCW Rework guarantees every open pack hits exact weight before sealing. It safeguards your brand, cuts waste, and boosts efficiency by auto-diverting out-of-spec packs. Stay compliant and customer-focused with easy rework and precision monitoring, powered by a 15.6″ touchscreen and full MARCO Yield Control integration.

This intelligent system protects your brand reputation by delivering consistent, high-quality products, reduces costly waste by correcting errors before sealing, boosts efficiency through automatic detection and diversion of out-of-spec packs, and helps you stay compliant with stringent quality standards. With operator-friendly rework and precision monitoring, you can maintain accuracy, cut costs, and keep your customers satisfied.

Videos

| Technical Specifications | |

| Size (W x H x D) | 2462 x 1447 x 1456 mm |

| Belt Weight Checking System | Five-belt |

| Maximum Product Dimension (LxWxH) | 200mm x 200mm x 120mm |

| Belt Width | 250mm |

| Speed | Up to 90ppm (pack & product dependent) |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Designed for open products to make corrective adjustments pre-seal/close ▪ Supermarket Compliant ▪ UK Weights and Measures approved |

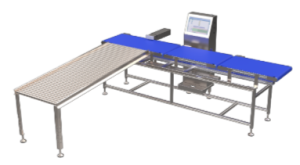

MCW Bulk XL Checkweigher

Built for Big Performance

Built for larger, bulkier items, this robust checkweigher ensures every pack meets exact weight specs before sealing. It cuts waste, boosts efficiency, and safeguards compliance.

With a 15.6″ touchscreen and MARCO Yield Control integration, you get real-time feedback and full production visibility, maximising throughput while protecting your brand.

| Technical Specifications | |

| Size (W x H x D) | 2841mm x 1391mm x 2915mm |

| Belt Weight Checking System | Three-belt |

| Maximum Product Dimension (LxW) | 700mm x 500mm |

| Belt Width | 500mm |

| Speed | Up to 60cpm |

| Reject Method | Air, Arm or Pusher |

| Key Features | ▪ Food grade belts ▪ Direct integration with MARCO Yield Control Module ▪ Up/downstream interlock connection ▪ Anti-gravity roller reject conveyor |

| Options | 2m Roller Reject Conveyor |

MCW Carton

Seal Confidence into Every Carton

Built for high-volume carton handling, the MCW Carton ensures precise weight control. This heavy-duty system boosts efficiency and cuts waste by flagging out-of-spec cartons early.

Operators enjoy fast setup via a 15.6″ touchscreen, while full MARCO Yield Control integration delivers real-time feedback and office-level oversight.

| Technical Specifications | |

| Size (W x H x D) | 1543mm x 1391mm x 1566mm |

| Belt Weight Checking System | Three-belt |

| Maximum Product Dimension (LxW) | 600mm x 400mm |

| Belt Width | 240mm |

| Speed | Up to 60cpm |

| Reject Method | Pusher |

| Key Features | ▪ Food grade belts ▪ Direct integration with MARCO Yield Control Module ▪ Visual Beacon Alarm Mode |