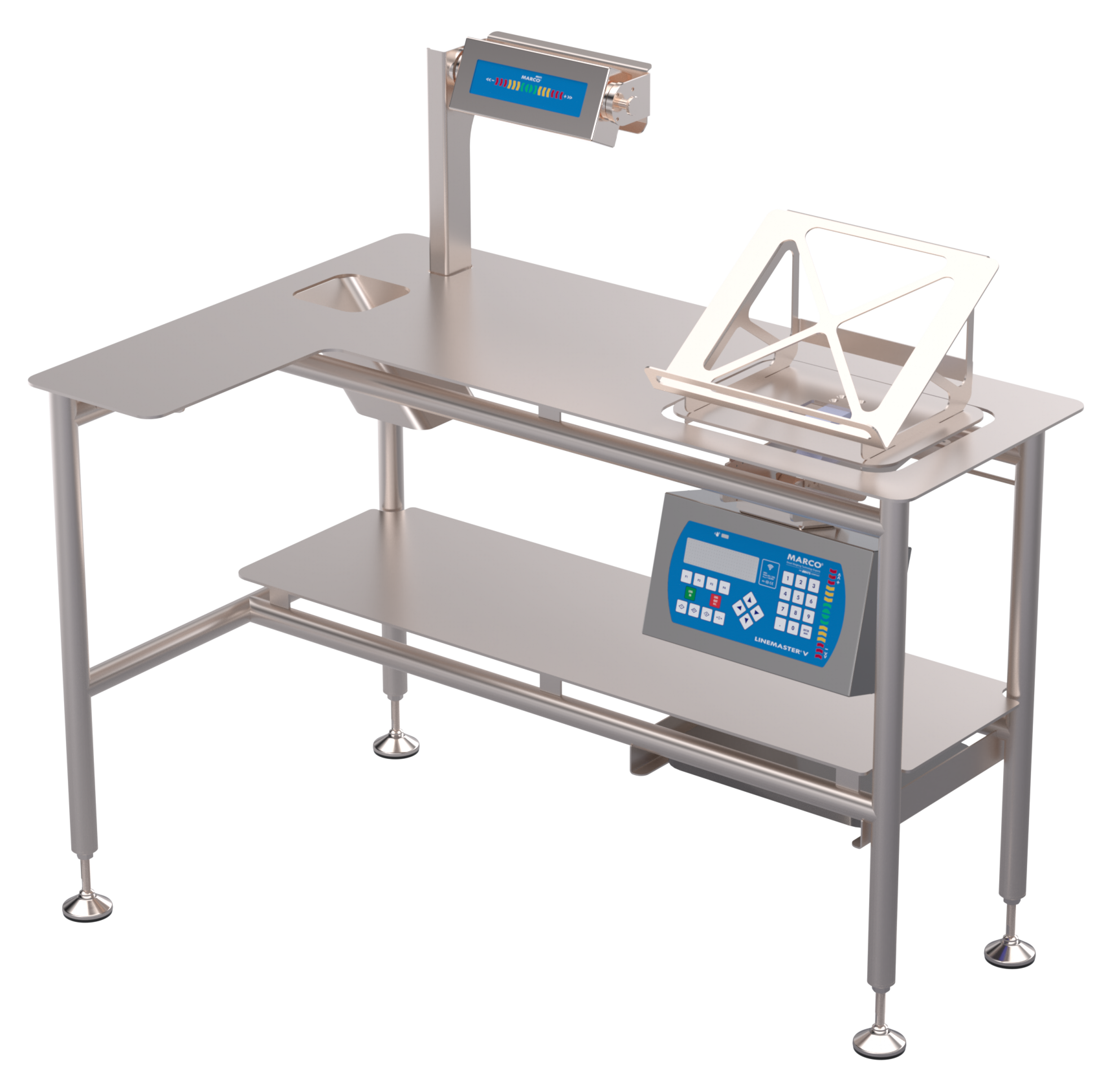

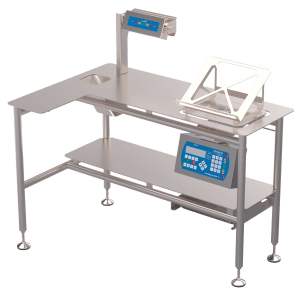

LMV Facing the Line Repack Workstation

Precision Packing – Every Time

Designed for precision and simplicity, MARCO workstations feature twin traffic-light indicators for effortless weighing and perfect results every time.

Built for lean workflows, they provide easy access for inspection, sorting, and assembly, with integrated shelves to keep materials within reach, reducing downtime and boosting efficiency.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1243 x 930 x 500 mm |

| Unit Weight | 61kg |

| Min Capacity | 20g |

| Max Capacity | 15kg |

| Max container size | 250 x 250 mm |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ High Speed Portion Control ▪ Removable angled tray holder on scale ▪ Remote Light Bar on swivel mount ▪ Height adjustable and designed for comfort ▪ Operator accountability via approved ID login ▪ Configurable weighing filters ▪ Simple installation onto customer’s existing weighing surfaces |

LMV Fine Balance Workstation

Delicate Products, Handled With Precision

Designed for herbs and other delicate items, this workstation minimises contact to preserve freshness and prevent bruising or tearing.

Featuring MARCO’s intuitive traffic-light system and Yield Control software, it delivers precision, consistency, and compliance, while protecting product quality and boosting efficiency.

Videos

| Technical Specifications | |

| Size mm (W x H x D) | 1452 x 1315 x 730 mm |

| Unit Weight | 61kg |

| Min Capacity | 20g |

| Max Capacity | 15kg |

| Max container size | 600mm x 400mm x 250mm |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ High Speed Portion Control ▪ Remote Light Bar on swivel mount ▪ Height adjustable and designed for comfort ▪ Operator accountability via approved ID login ▪ Configurable weighing filters ▪ Simple installation onto customer’s existing weighing surfaces |

LMV Dual Weighing Facing the Line Workstation

Accuracy You Can See – Comfort You Can Feel

Boost productivity with an operator-friendly design that keeps you in front of the conveyor.

MARCO’s twin LED traffic-light system ensures accurate portioning and less waste. Includes ergonomic scale pans, lower shelving, and an integrated waste chute for a cleaner, faster workflow.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1330 x 900 x 900 mm |

| Unit Weight | 93kg |

| Min Capacity | 20g |

| Max Capacity | 15kg |

| Max container size | 600mm x 400mm x 250mm |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Removable angled tray holder on scale ▪ Real time production data tracking ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

| Options | Also available as Twin Workstation |

Twin CheckMaster Workstation

Streamlined Sorting – Superior Results

Built for rapid, precise grape and soft fruit portioning, this workstation combines speed and accuracy with an integrated scale pan, dual waste chutes, and tray holders for smooth handling.

Overhead lighting ensures clear inspection, while the traffic light system and MARCO Yield Control software deliver consistent results and operational excellence.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1240 x 1995 x 1650 mm |

| Unit Weight | 220kg |

| Min Capacity | 20g |

| Max Capacity | 12kg |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Real time production data tracking ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

Twin AutoDrive Workstation

Continuous Supply – Zero Lifting

Eliminate manual lifting with a system that moves containers from line to workstation for a continuous flow and maximum safety.

Operators can store up to three boxes, with extra containers buffered for uninterrupted processing. MARCO’s traffic-light system and Yield Control software ensure precision and consistency every time.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1940 x 1247 x 2169 mm |

| Unit Weight | 390kg |

| Min Capacity | 20g |

| Max Capacity | 15kg |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Ergonomic design ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

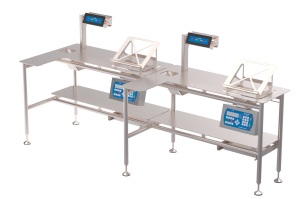

Twin LMV Dual Weighing Facing the Line Workstation

Ergonomics That Drive Efficiency

Designed for natural posture and smooth workflow, this dual-facing workstation keeps operators in front of the conveyor for maximum productivity.

Features include lower shelves, ergonomic scale pans, integrated waste chutes, MARCO’s twin traffic-light system, and Yield Control software, all in a space-saving design.

Videos

| Technical Specifications | |

| Size (W x H x D) | 2670 x 1281 x 900 mm |

| Unit Weight | 183kg |

| Min Capacity | 20g |

| Max Capacity | 12kg |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Ergonomic design ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

LMV Facing the Line Repack Workstation

Precision Packing – Every Time

Designed for precision and simplicity, MARCO workstations feature twin traffic-light indicators for effortless weighing and perfect results every time.

Built for lean workflows, they provide easy access for inspection, sorting, and assembly, with integrated shelves to keep materials within reach, reducing downtime and boosting efficiency.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1243 x 930 x 500 mm |

| Unit Weight | 61kg |

| Min Capacity | 20g |

| Max Capacity | 15kg |

| Max Container Size | 250 x 250mm |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ High Speed Portion Control ▪ Removable angled tray holder on scale ▪ Remote Light Bar on swivel mount ▪ Height adjustable and designed for comfort ▪ Operator accountability via approved ID login ▪ Configurable weighing filters ▪ Simple installation onto customer’s existing weighing surfaces |

LMV Fine Balance Workstation

Delicate Products, Handled With Precision

Designed for herbs and other delicate items, this workstation minimises contact to preserve freshness and prevent bruising or tearing.

Featuring MARCO’s intuitive traffic-light system and Yield Control software, it delivers precision, consistency, and compliance, while protecting product quality and boosting efficiency.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1452 x 1315 x 830 mm |

| Unit Weight | 61kg |

| Min Capacity | 20g |

| Max Capacity | 12kg |

| Max container size | 600mm x 400mm x 250mm |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Height adjustable and designed for comfort ▪ Real time production data tracking ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

LMV Dual Weighing Facing the Line Workstation

Accuracy You Can See – Comfort You Can Feel

Boost productivity with an operator-friendly design that keeps you in front of the conveyor.

MARCO’s twin LED traffic-light system ensures accurate portioning and less waste. Includes ergonomic scale pans, lower shelving, and an integrated waste chute for a cleaner, faster workflow.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1330 x 900 x 900 mm |

| Unit Weight | 93kg |

| Min Capacity | 20g |

| Max Capacity | 15kg |

| Max container size | 600mm x 400mm x 250mm |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Real time production data tracking ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

| Options | Also available as Twin Workstation |

Twin CheckMaster Workstation

Streamlined Sorting – Superior Results

Built for rapid, precise grape and soft fruit portioning, this workstation combines speed and accuracy with an integrated scale pan, dual waste chutes, and tray holders for smooth handling.

Overhead lighting ensures clear inspection, while the traffic light system and MARCO Yield Control software deliver consistent results and operational excellence.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1240 x 1995 x 1650 mm |

| Unit Weight | 220kg |

| Min Capacity | 20g |

| Max Capacity | 12kg |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Real time production data tracking ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

Twin AutoDrive Workstation

Continuous Supply – Zero Lifting

Eliminate manual lifting with a system that moves containers from line to workstation for a continuous flow and maximum safety.

Operators can store up to three boxes, with extra containers buffered for uninterrupted processing. MARCO’s traffic-light system and Yield Control software ensure precision and consistency every time.

Videos

| Technical Specifications | |

| Size (W x H x D) | 1940 x 1205 x 2150 |

| Unit Weight | 390kg |

| Min Capacity | 20g |

| Max Capacity | 12kg |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Real time production data tracking ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |

Twin LMV Dual Weighing Facing the Line Workstation

Ergonomics That Drive Efficiency

Designed for natural posture and smooth workflow, this dual-facing workstation keeps operators in front of the conveyor for maximum productivity.

Features include lower shelves, ergonomic scale pans, integrated waste chutes, MARCO’s twin traffic-light system, and Yield Control software, all in a space-saving design.

Videos

| Technical Specifications | |

| Size (W x H x D) | 2670 x 1281 x 900 mm |

| Unit Weight | 183kg |

| Min Capacity | 20g |

| Max Capacity | 12kg |

| Packaging Types | Bags, Clamshells, Punnets, Boxes |

| Key Features | ▪ Language transparent sixteen segment LED traffic light display ▪ Real time production data tracking ▪ Operator accountability via approved ID login ▪ Configurable weighing filters |