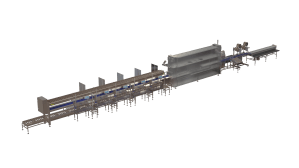

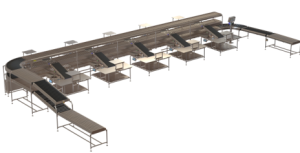

Multi Tier Modular Packing Lines

Efficiency at Every Tier

Boost efficiency and cut costs with the Multi-Tier Packing Line. Designed for speed and precision, it empowers operators to pack punnets, clamshells, and bags effortlessly.

Dual CheckMaster scales at every station ensure perfect weight control, reducing giveaway and waste while maintaining consistent quality. Streamlined operations mean faster throughput, lower labour costs, and maximum profitability.

| Key Features | ▪ Low energy consumption ▪ Ergonomic workstation ▪ Roller conveyors for auto index delivery and removal of boxes ▪ Modular design ▪ Raw Product Zone Controlled Conveyor ▪ Detailed batch and individual operator reporting ▪ Recipe Set Up |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ Varying Workstation Options ▪ PDD Screens ▪ Checkweigher & Metal Detector ▪ End of line Case Packers ▪ Out of frame punnet conveyors ▪ Waste Conveyor |

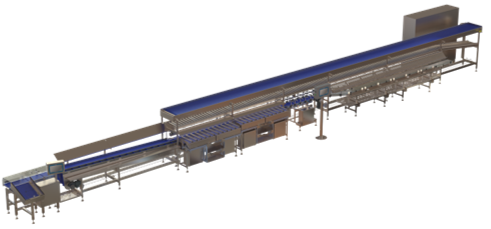

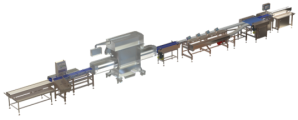

Automatic Top Up Line

Less Labour – More Output

Revolutionise your packing process with MARCO’s Automatic Top Up Line. By automating key tasks, it slashes labour costs, minimises waste, and guarantees consistent, high-quality packs.

By automating key aspects of the packing process, this system drastically reduces the need for manual labour, resulting in lower operational costs and higher profitability.

Boost productivity, cut expenses, and elevate your profitability, all in one smart solution.

Videos

| Key Features | ▪ Automatic raw material feed ▪ Automatic empty box return ▪ Advanced 3-point Quality Control ▪ Automatic grape weighing ▪ Automatic produce dispensing into punnet ▪ Dynamic weighing ▪ 2-point inspection lighting ▪ Real time run data and diagnostics |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ End of Line Case Packer ▪ Single/Twin Lane ▪ Add additional Inline SelectMaster Automatic ▪ Checkweigher & Metal Detector ▪ Add/remove operator positions ▪ Auto Drive Transfers |

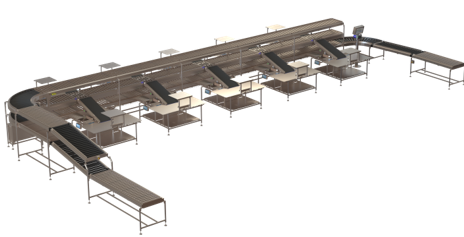

Auto Drive Packing Line

Efficiency Meets Safety

Take the strain out of packing with MARCO’s Auto Drive Packing Line. Designed to eliminate heavy lifting and minimise manual handling, it dramatically reduces the risk of injuries and accidents. At the push of a button, full boxes of raw material are delivered straight to the operator’s workstation.

This is accomplished through an automated system that drives full boxes of raw material directly to the operator’s workstation at the push of a button. Once the contents have been reworked the operator can simply slide the completed box back onto the conveyor eliminating the need for lifting, as would be required with a conventional tiered conveyor system.

Videos

| Key Features | ▪ Automatic transfer of boxes ▪ Low energy consumption ▪ Roller conveyors for auto index delivery and removal of boxes ▪ Ergonomic workstation ▪ Modular design ▪ Detailed batch and individual operator reporting |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ Varying Workstation Options ▪ PDD Screens ▪ Checkweigher & Metal Detector ▪ End of line Case Packers ▪ Out of frame punnet conveyors ▪ Inside frame punnet conveyors ▪ Waste Conveyor |

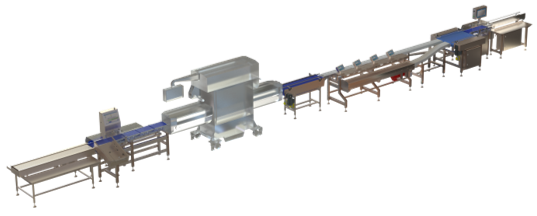

Check-Weigh & Rework Line

Fast Checks – Smart Adjustments – Perfect Packs

MARCO’s Check Weigh & Rework Line ensures every pack meets your standards before moving downstream. 100% of products are dynamically checkweighed, so labour is only used where adjustments are needed.

Compression-free conveyors deliver containers to ergonomic workstations for quick checks and effortless corrections, reducing strain and boosting productivity.

Videos

| Key Features | ▪ Low energy consumption ▪ Roller conveyors for auto index delivery and removal of boxes ▪ Ergonomic workstation ▪ Modular design ▪ Detailed batch and individual operator reporting |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ Front & End Robotics ▪ Single/Twin Lane ▪ Checkweigher & Metal Detector ▪ Add/Remove Workstations |

Multi Tier Modular Packing Lines

Efficiency at Every Tier

Boost efficiency and cut costs with the Multi-Tier Packing Line. Designed for speed and precision, it empowers operators to pack punnets, clamshells, and bags effortlessly.

Dual CheckMaster scales at every station ensure perfect weight control, reducing giveaway and waste while maintaining consistent quality. Streamlined operations mean faster throughput, lower labour costs, and maximum profitability.

| Key Features | ▪ Low energy consumption ▪ Ergonomic workstation ▪ Roller conveyors for auto index delivery and removal of boxes ▪ Modular design ▪ Raw Product Zone Controlled Conveyor ▪ Detailed batch and individual operator reporting ▪ Recipe Set Up |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ Varying Workstation Options ▪ PDD Screens ▪ Checkweigher & Metal Detector ▪ End of line Case Packers ▪ Out of frame punnet conveyors ▪ Waste Conveyor |

Automatic Top Up Line

Less Labour – More Output

Revolutionise your packing process with MARCO’s Automatic Top Up Line. By automating key tasks, it slashes labour costs, minimises waste, and guarantees consistent, high-quality packs.

Boost productivity, cut expenses, and elevate your profitability, all in one smart solution.

| Key Features | ▪ Automatic raw material feed ▪ Automatic empty box return ▪ Advanced 3-point Quality Control ▪ Automatic grape weighing ▪ Automatic produce dispensing into punnet ▪ Dynamic weighing ▪ 2-point inspection lighting ▪ Real time run data and diagnostics |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ End of Line Case Packer ▪ Single/Twin Lane ▪ Add additional Inline SelectMaster Automatic ▪ Checkweigher & Metal Detector ▪ Add/remove operator positions ▪ Auto Drive Transfers |

Videos

Auto Drive Packing Line

Efficiency Meets Safety

Take the strain out of packing with MARCO’s Auto Drive Packing Line. Designed to eliminate heavy lifting and minimise manual handling, it dramatically reduces the risk of injuries and accidents. At the push of a button, full boxes of raw material are delivered straight to the operator’s workstation.

| Key Features | ▪ Automatic transfer of boxes ▪ Low energy consumption ▪ Roller conveyors for auto index delivery and removal of boxes ▪ Ergonomic workstation ▪ Modular design ▪ Detailed batch and individual operator reporting |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ Varying Workstation Options ▪ PDD Screens ▪ Checkweigher & Metal Detector ▪ End of line Case Packers ▪ Out of frame punnet conveyors ▪ Inside frame punnet conveyors ▪ Waste Conveyor |

Videos

Check-Weigh & Rework Line

Fast Checks – Smart Adjustments – Perfect Packs

MARCO’s Check Weigh & Rework Line ensures every pack meets your standards before moving downstream. 100% of products are dynamically checkweighed, so labour is only used where adjustments are needed.

Compression-free conveyors deliver containers to ergonomic workstations for quick checks and effortless corrections, reducing strain and boosting productivity.

Videos

| Key Features | ▪ Low energy consumption ▪ Roller conveyors for auto index delivery and removal of boxes ▪ Ergonomic workstation ▪ Modular design ▪ Detailed batch and individual operator reporting |

| Produce | ▪ Grapes ▪ Strawberries ▪ Raspberries ▪ Mushrooms ▪ Tomatoes |

| Options | ▪ Front & End Robotics ▪ Single/Twin Lane ▪ Checkweigher & Metal Detector ▪ Add/Remove Workstations |